HIOKI BT3564 Battery HiTester – 1000V High-Voltage Battery Pack Tester for EV & Energy Storage Applications

The Challenge: Accurate Testing for High-Voltage Battery Packs

As New Zealand accelerates its transition toward electric vehicles and grid-scale energy storage, technicians and quality assurance teams face a critical challenge: how do you safely and accurately test battery packs operating at voltages that would damage conventional test equipment?

Standard battery testers typically max out at 60V, leaving EV service centres, battery manufacturers, and energy storage integrators scrambling for solutions when dealing with modern high-voltage architectures. Testing pack-level resistance and voltage separately wastes time on production lines, while inconsistent measurement techniques introduce variability that can mask developing faults in cell connections, bus bars, and weld joints.

The consequences of inadequate testing extend beyond compliance concerns. Missed resistance anomalies in battery pack assemblies can lead to thermal runaway events, warranty claims, and costly field failures that erode customer confidence and operational margins.

Precision Testing at Production-Line Speed

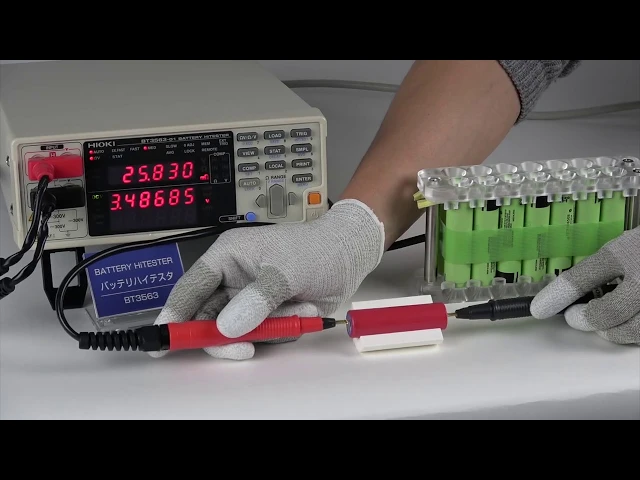

The HIOKI BT3564 Battery HiTester addresses these challenges head-on with a 1000V DC input capability that handles everything from residential storage batteries to full EV and PHEV packs. Rather than treating resistance and voltage as separate measurements, the BT3564 captures both parameters simultaneously during each test cycle, cutting measurement time in half compared to sequential testing approaches.

Seven resistance ranges spanning 3mΩ to 3kΩ accommodate the full spectrum of battery pack testing requirements. The ultra-sensitive 3mΩ range with 0.1μΩ resolution detects subtle variations in bus bar connections and tab welds that indicate potential weak points. Higher ranges handle total pack resistance measurements where cumulative cell resistance values can reach several ohms.

Accuracy specifications of ±0.5% reading ±5 digits across most ranges ensure your measurements reflect actual pack condition rather than instrument uncertainty. The 1kHz AC-IR measurement method employed by the BT3564 provides highly repeatable results that correlate reliably with battery health indicators, giving quality control teams confidence in pass/fail decisions.

Built for High-Voltage Safety

Working with battery packs at hundreds of volts demands respect for the energy stored within. The BT3564 incorporates HIOKI’s spark discharge reduction function that limits inrush current when probes contact charged terminals. This prevents the arc flash and electrode damage that can occur when connecting to high-voltage sources, protecting both operators and the batteries under test.

Three voltage measurement ranges covering 10V to 1000V DC with 10μV minimum resolution capture open-circuit voltage readings with laboratory-grade precision. The ±0.01% reading accuracy on voltage measurements exceeds typical handheld multimeter specifications by an order of magnitude, essential for detecting the small voltage deviations that indicate cell imbalances within assembled packs.

Optional 1000V-rated measurement leads and probes designed specifically for high-voltage battery applications ensure your test connections maintain the safety margins required for production environments. Pin-type leads with replaceable tips provide reliable four-terminal Kelvin connections that eliminate lead resistance errors from your measurements.

Production Integration Made Simple

The BT3564 slots seamlessly into automated test stations and production line workflows. Built-in comparator functions provide independent high/low limit checking for both resistance and voltage parameters, with pass/fail results available via external I/O outputs for PLC integration. Set your acceptance thresholds once, and the instrument handles sorting decisions automatically.

Three sampling speed options accommodate different testing scenarios. The 12ms FAST mode maximises throughput on production lines where every second counts. MEDIUM and SLOW modes progressively increase averaging for improved stability when characterising reference cells or investigating anomalies.

Analog output of measured resistance values enables real-time monitoring when connected to data loggers or chart recorders, creating continuous quality records that support traceability requirements. RS-232C and GP-IB interfaces provide programming access for custom test sequences and data acquisition systems, while the included sample application software simplifies initial setup and operation.

Applications Across the Battery Industry

EV and PHEV Manufacturing: Production-line testing of assembled battery packs before installation into vehicles, verifying total pack resistance and voltage meet specifications.

Battery Pack Assembly: Quality verification of cell-to-cell connections, bus bar welds, and terminal joints where resistance anomalies indicate manufacturing defects.

Energy Storage Systems: Commissioning and periodic maintenance testing of grid-scale and residential battery storage installations, ensuring pack performance remains within acceptable limits.

Second-Life Battery Assessment: Evaluating decommissioned EV batteries for suitability in stationary storage applications, where accurate resistance measurements inform grading decisions.

R&D and Cell Development: Laboratory characterisation of prototype cells and pack configurations, capturing baseline measurements for degradation studies and lifecycle testing.

Service and Warranty: Diagnosing customer complaints and warranty claims by measuring pack-level parameters that indicate whether issues stem from cell degradation or connection failures.

Training and Education: Demonstrating battery measurement techniques to automotive technicians transitioning into EV service roles, using an instrument they’ll encounter in professional workshops.