HIOKI RM3545A-1 Precision Resistance Meter – Laboratory-Grade Accuracy for Production Line Testing

The Challenge: When Resistance Measurements Make or Break Your Quality Control

In today’s high-stakes manufacturing environment, particularly across EV components, battery assemblies, and precision electrical connections, the difference between a quality weld and a potential failure often comes down to microohms. Traditional resistance meters struggle to detect these critical variations, leaving quality teams relying on visual inspections or destructive testing that can’t scale.

New Zealand manufacturers supplying the automotive, renewable energy, and electrical infrastructure sectors face mounting pressure to document every connection’s integrity. Whether you’re verifying busbar welds in a battery pack, testing conductor joints in switchgear, or qualifying cable terminations for mining equipment, guesswork isn’t an option. Compliance with AS/NZS standards and OEM specifications demands quantitative evidence that each connection meets requirements.

The real cost of inadequate resistance testing? Warranty claims, field failures, and the kind of quality escapes that damage hard-won reputations in tight-knit trade communities.

The Solution: Precision That Travels from Lab to Production Line

The HIOKI RM3545A-1 bridges the gap between laboratory-grade metrology and production floor practicality. Unlike bench instruments that demand ideal conditions, this resistance meter is engineered for real-world manufacturing environments where cable runs are long, contact resistance varies, and throughput matters.

At its core, the RM3545A-1 delivers 0.045% basic accuracy with resolution down to 1 nanoohm—precision that allows you to detect resistance variations smaller than a grain of sand’s worth of copper. The instrument’s 13 measurement ranges span from 1 nΩ all the way to 1200 MΩ, covering everything from busbar micro-welds to insulation resistance verification in a single unit.

What truly sets this meter apart is its high path resistance tolerance. Where conventional instruments lose accuracy when connected through long cables or automated switching systems, the RM3545A-1 maintains specified accuracy even with significant wiring and contact resistance in the measurement path. This means you can embed it directly into automated test equipment without obsessing over every connection’s contribution to measurement uncertainty.

Key Benefits That Matter on the Job

Quantitative Weld Quality Management

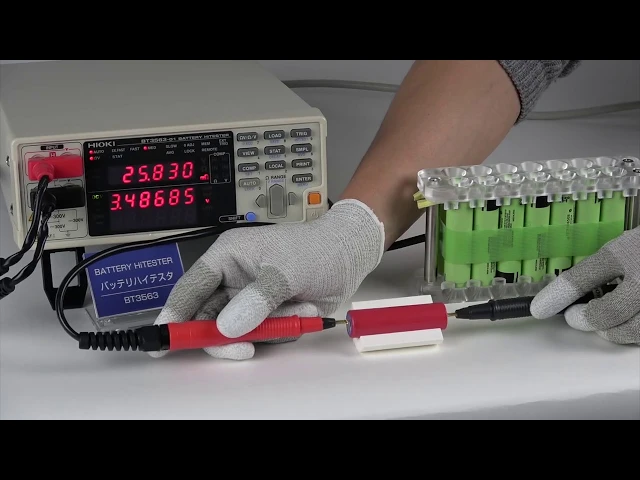

Stop relying on visual inspection alone. The RM3545A-1 transforms weld quality assessment from subjective judgment into documented, traceable data. A properly executed weld typically measures between 10 µΩ and 100 µΩ—variations the instrument detects with its 1000 µΩ range at 1 nΩ resolution. Set pass/fail limits using the built-in comparator, and you’ve got 100% inspection capability that catches defects before they leave your facility.

Offset Voltage Compensation (OVC) for Thermoelectric Accuracy

When dissimilar metals meet—as they do in virtually every busbar connection—thermoelectric voltages can throw off low-resistance measurements. The RM3545A-1’s OVC function automatically compensates for these EMF effects, delivering stable, accurate readings even when measuring copper-aluminium transitions or nickel-plated busbars common in battery pack construction.

Temperature-Corrected Results for Consistent Standards

Resistance changes with temperature, and a measurement taken at 35°C means something different than one taken at 20°C. The included Z2001 temperature sensor enables automatic correction to your reference temperature, ensuring measurements remain comparable across shifts, seasons, and facilities. For teams working to IEC or AS/NZS standards, this eliminates a major source of measurement variation.

Production-Ready Speed and Integration

At 21ms per measurement in FAST mode, the RM3545A-1 keeps pace with modern production lines. Standard LAN, USB, and RS-232C interfaces support direct integration with factory automation systems, PLCs, and data collection software. The command monitor function displays communication traffic in real-time, cutting system integration debugging time dramatically. LabVIEW drivers are available for test system developers.

Applications Across New Zealand Industries

EV and Battery Manufacturing

New Zealand’s emerging battery industry demands the same quality standards as global automotive OEMs. The RM3545A-1 provides the measurement capability needed for cell interconnect verification, busbar weld testing, and module assembly QC. Document every connection in your battery packs with traceable, compliant measurements.

Electrical Switchgear and Distribution

For manufacturers and maintenance teams working on switchboards, busbars, and power distribution equipment, low-resistance testing verifies that bolted and crimped connections meet specifications. The high path resistance tolerance makes site testing practical even with standard test leads.

Cable and Harness Manufacturing

Verify crimp quality and conductor resistance across harness assemblies. The comparator function enables rapid go/no-go testing while data logging captures every measurement for quality records.

Research, Development and Calibration Laboratories

When developing new connection technologies or establishing manufacturing processes, laboratory-grade accuracy matters. The RM3545A-1 delivers the precision needed for R&D characterisation while remaining robust enough for production validation.

Mining and Resources Equipment

High-current connections in mining equipment demand reliable resistance testing. Verify splices, terminations, and bonding connections meet specifications for safe, efficient operation in demanding environments.